Sunny Optical Public Test Platform

Core Advantages

Authoritative Certification

The laboratory is CNAS-accredited and has reliable, professional laboratory management.

Multi-category Testing Capabilities

Comprehensive testing types more than 50 test items of various categories can be carried out.

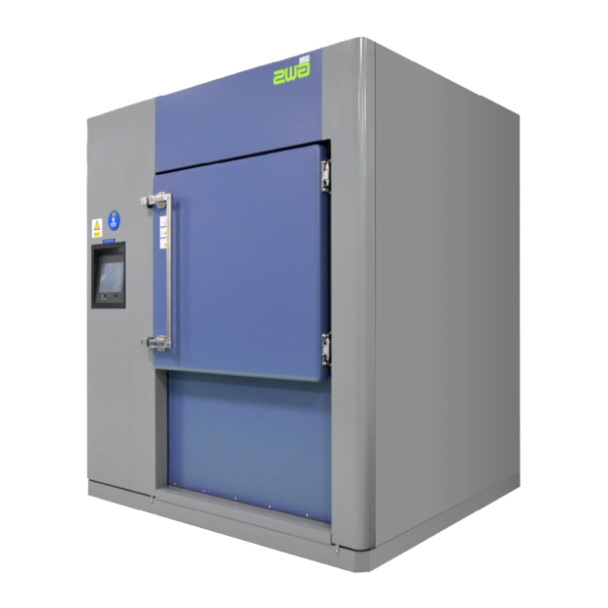

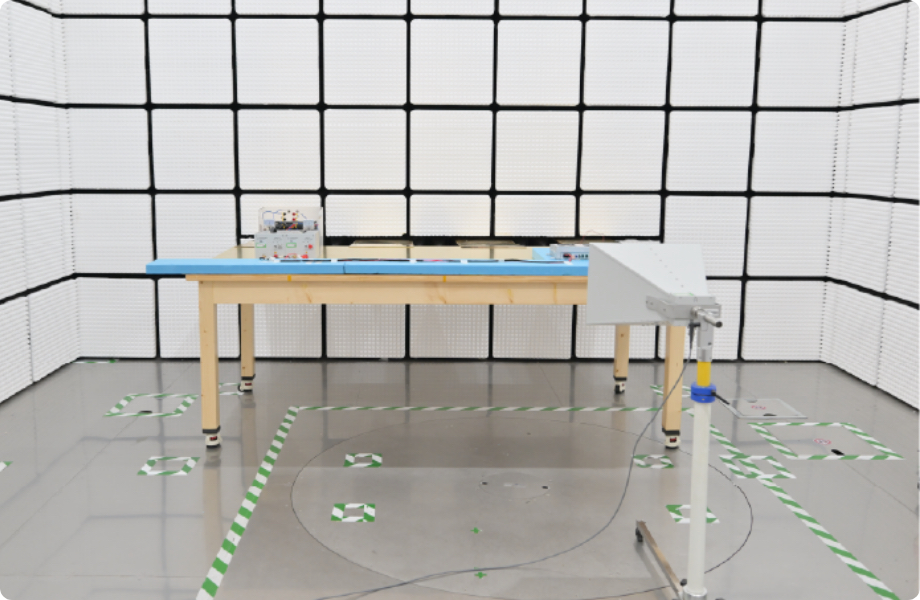

Professional Equipment

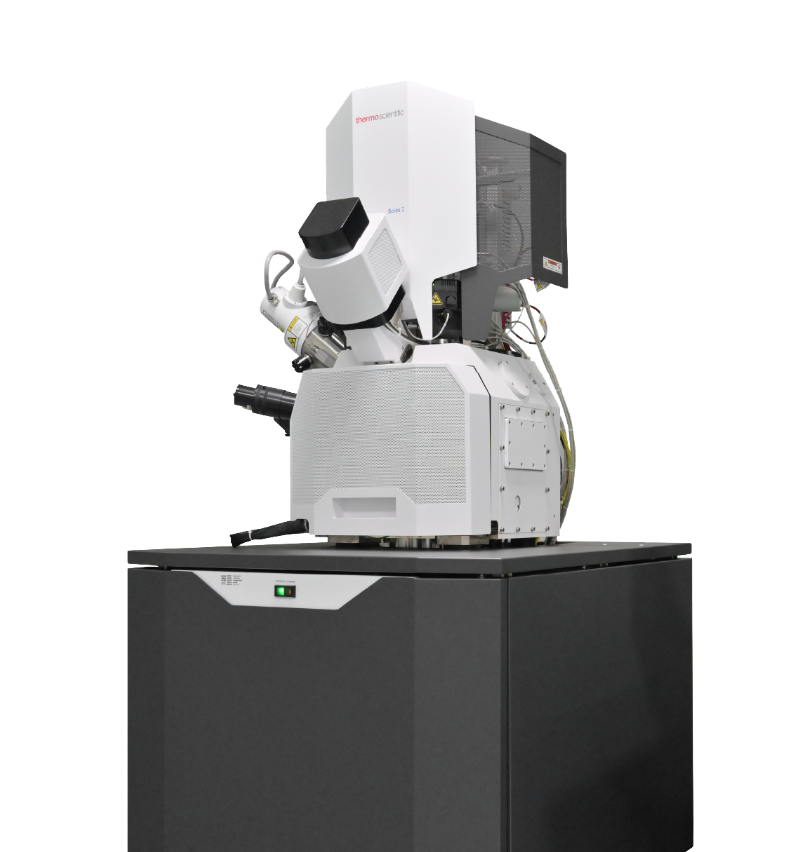

Equipped with high-precision testing equipment.

There are more than 140 large-scale instruments and equipment.

Professional Team

Equipped with an experienced professional team to provide high-quality services.

Quality Assurance

Recognized by multiple well-known major automotive OEMs.

Testing Solutions

Laboratory Introduction

Sunny Optical Test Laboratory

The laboratory was jointly established by Zhejiang Intelligent Optical Perception Innovation Center and Sunny Optical Technology Co., Ltd. It is a comprehensive laboratory with reliability testing, electromagnetic compatibility testing, material testing and failure analysis as its core.

CNAS Certification

Available Test Items

| Environmental Reliability Test | EMC Test | Material Test | Failure Analysis |

| Salt Spray Test | Radiated Emissions of Components/Modules – ALSE Method | TMA (Thermomechanical Analyzer) | Nondestructive Testing CT |

| Low Temperature Test | Conducted Emissions from Components/Modules – Voltage Method | Refractive Index and Refractive Index Dn/Dt | Microscopic Morphology Measurement and Analysis SEM |

| High Temperature Test | Conducted Emissions From Components/Modules – Current Probe Method | Component Analysis EDS | |

Constant Temperature | Radiated Interference Immunity – Anechoic Chamber Method | Focused Ion Beam Cutting FIB | |

Humidity Test Damp Heat Cycling Test | Electrostatic Discharge Immunity | ||

| Temperature/Humidity Combined Cycle Test | Power Line Transient Conduction Interference Immunity | ||

| Temperature Changes | Bulk Current Injection (BCI) | ||

| Vibration (Sinusoidal) | Portable Handheld Transmitter Anti-interference | ||

| Broadband Random Vibration Test | Signal Line Coupling Anti-interference | ||

| Drop Test | Low Frequency Magnetic Field Emission | ||

| Temperature Cycle and Sinusoidal Vibration Random Vibration Comprehensive Test | DC Voltage Operating Range | ||

| Comprehensive Tests of Climate (Temperature, Humidity) and Dynamics (Vibration, Shock) | Overvoltage | ||

| Shock | Superimposed AC | ||

| Solar Radiation Test | Supply Voltage Ramp Down and Ramp Up | ||

| Dust Test | The Supply Voltage Drops Momentarily | ||

| Withstand Voltage Insulation Resistance Tester | |||

| Reset Characteristics | |||

| Startup Features | |||

| Load Dump | |||

| Reverse Voltage | |||

| Open Circuit | |||

| Short Circuit Protection |

Contact Details

- Tel:0574-62530919

- Email:syts@sunnyoptical.com

- Address:Laboratory Buliding, 67-69 Fengle Road, Yuyao, Zhejiang, China